Bending Animation

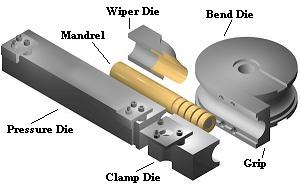

What is tube bending and how does it work? Tube bending as a process starts with loading a tube into a pipe bender and clamping it into place between two dies, the clamping block and the forming die. The tube is also loosely held by two other dies, the wiper die and the pressure die. The process of tube bending involves using mechanical force to push stock material pipe or tubing against a die, forcing the pipe or tube to conform to the shape of the die. Often, stock tubing is held firmly in place while the end is rotated and rolled around the die. Other forms of processing including pushing stock through rollers that bend it into a simple curve. For some tube bending processing, a mandrel is placed inside the tube to prevent collapsing. The tube is also held in tension by a wiper die to prevent any creasing during stress. A wiper die is usually made of a softer alloy i.e. aluminum, brass to avoid scratching or damaging the material being bent. Much of the tooling is made of hardened steel or tooled steel to maintain and prolong the tools life. However wherever there is a concern of scratching or gouging the work piece, a softer material such as aluminum or bronze is utilized. For example, the clamping block, rotating form block and pressure die are often formed from the hardened steel because the tubing is not moving past these parts of the machine. On the other hand, the pressure die and the wiping die are formed from aluminum or bronze to maintain the shape and surface of the workpiece as it slides by. Take a look at this short video to see how its done for yourself

|

© Copyright Hamilton Tube Bending

- Site map

|

Mob:0272372828